Characteristics and application analysis of galvanized coils

1. Definition and characteristics of galvanized coils

Aluzinc coils are a type of metal material that has been specially processed on a steel substrate. Its core feature is that a layer of aluminum-zinc alloy is plated on the surface of the substrate. This alloy layer combines the excellent characteristics of aluminum’s light weight, corrosion resistance, and zinc’s cathodic protection.

In terms of corrosion resistance, galvanized coils perform well. Due to the presence of the aluminum-zinc alloy layer, it can effectively resist corrosion in a variety of harsh environments. Whether it is a humid marine climate, an area with severe industrial pollution, or a chemical environment with large fluctuations in pH, galvanized coils can form a stable protective film with their unique corrosion mechanism, greatly extending their service life. For example, galvanized coils are used on the roofs of buildings in coastal areas. Even if they are eroded by sea breeze and seawater for a long time, they can maintain a good appearance and performance, effectively preventing rust perforation and other situations.

In terms of mechanical properties, it has good strength and toughness. This allows the galvanized coil to withstand certain deformation and stress during processing, making it convenient for cutting, bending, stamping and other processing techniques. For example, in the production of some parts for automobile manufacturing, galvanized coils can adapt well to the complex molding process requirements and provide reliable material guarantee for automobile parts.

In addition, galvanized coils also have good heat resistance. In high temperature environments, such as in some industrial high-temperature workshop buildings or hot water system applications, it will not lose performance as quickly as ordinary steel, and can maintain structural stability to ensure the normal operation of related facilities under high temperature conditions.

2. Application fields of galvanized coils

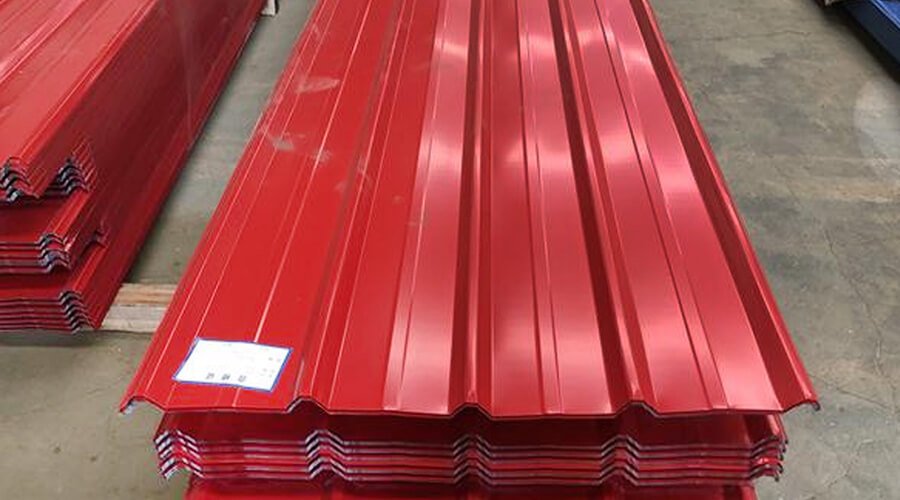

1. The construction field is one of the main application markets for galvanized coils. In the use of building roofs and walls, its excellent weather resistance and corrosion resistance can effectively protect the structure of the building. At the same time, galvanized coils can also be processed into various shapes and colors according to architectural design requirements, adding unique visual effects to the appearance of the building. For example, the roof and exterior wall decoration of some modern large-scale stadiums, airport terminals and other landmark buildings often use galvanized coil materials.

2. The automobile manufacturing industry also uses a large number of galvanized coils. In the manufacturing process of automobile bodies, it is used to make some chassis parts, body structural parts, etc. Its good corrosion resistance and mechanical properties can meet the long-term operation requirements of automobiles under different road conditions and use environments, and improve the overall reliability and safety of automobiles.

In short, galvanized steel coils play an important role in many fields such as construction and automobiles with their unique performance and advantages, and have become one of the indispensable materials in modern industry.