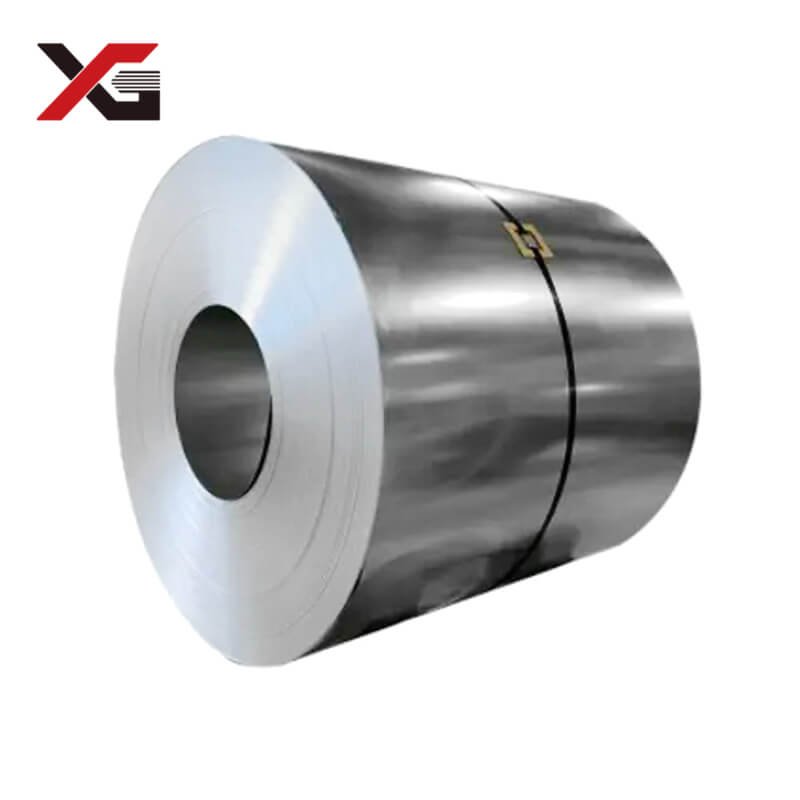

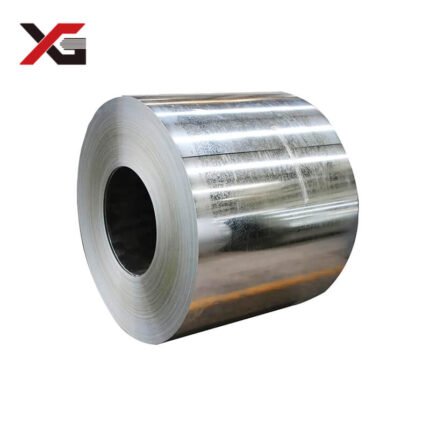

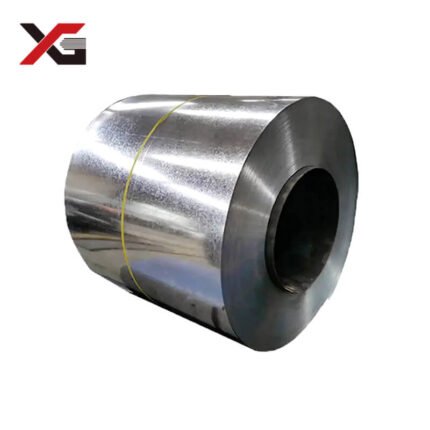

Hot Dipped A792 Aluzinc Galvalume Coil Sheet Aluzinc Zinc Aluminum Alloy Coated Steel GI Coil

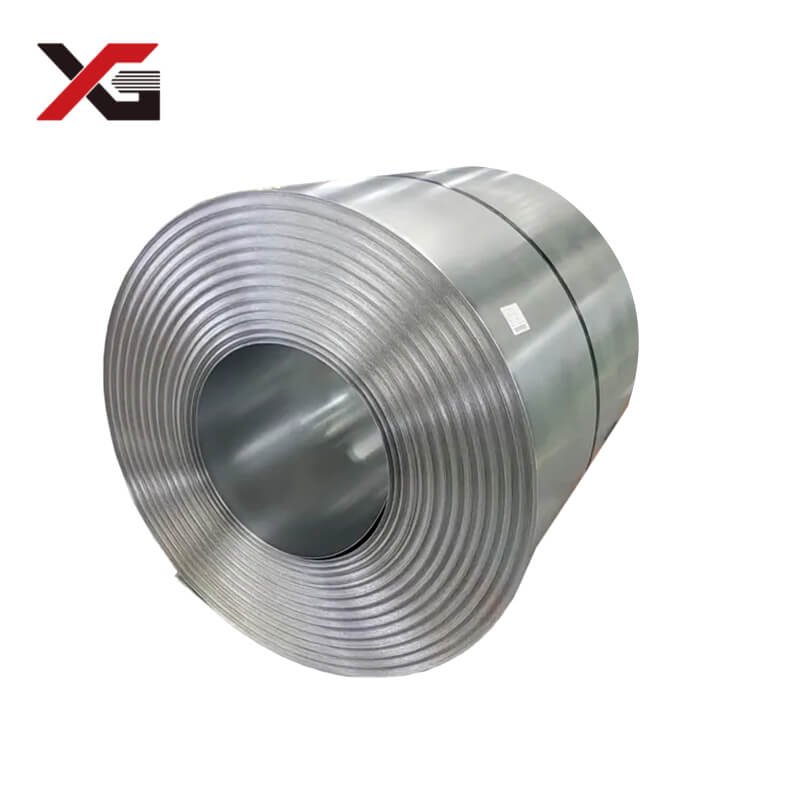

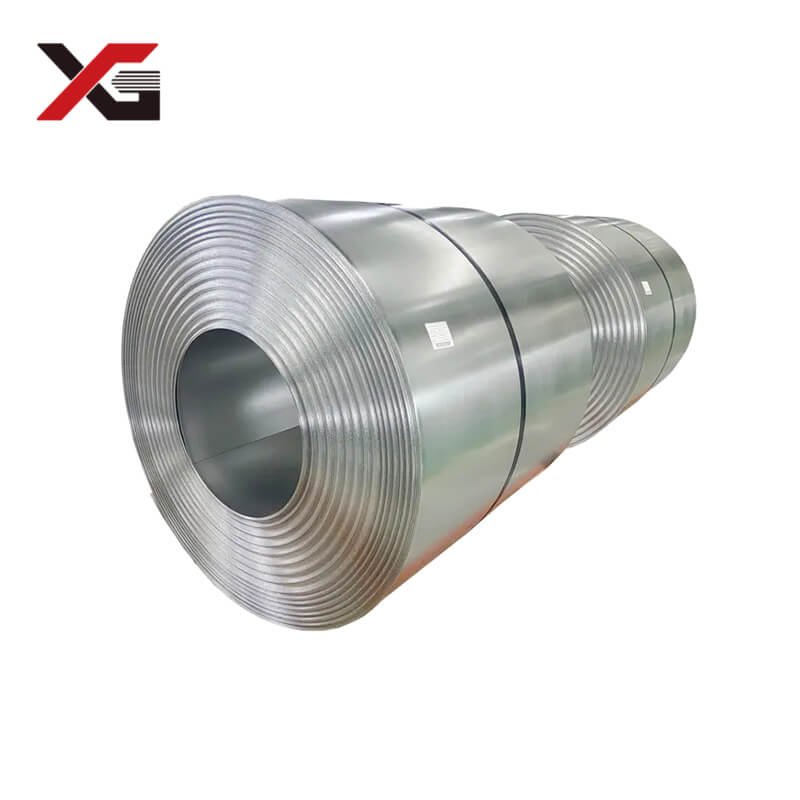

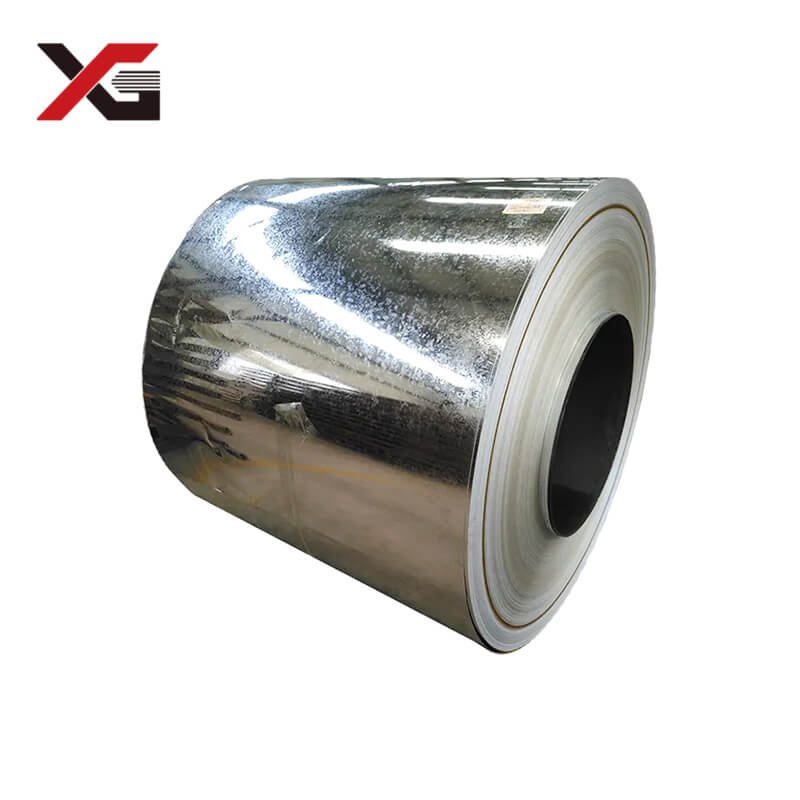

Aluminized zinc coil is an alloy material, mainly composed of aluminum (55%), zinc (43.4%) and silicon (1.6%) solidified at a high temperature of 600°C, forming a dense quaternary crystal.

Product Introduction

Galvalume coil is an alloy material formed by solidification of aluminum, zinc and a small amount of silicon at a high temperature of 600℃. Its main components include 55% aluminum, 43.4% zinc and 1.6% silicon. This unique combination of ingredients gives galvalume coil a number of excellent properties. It not only has excellent corrosion resistance, which is three times that of pure galvanized coil, but also has beautiful zinc flowers on the surface, making it an ideal choice for building exterior panels. In addition, galvalume coil also has good heat resistance and can withstand temperatures as high as more than 300 degrees Celsius, which is similar to the high-temperature oxidation resistance of aluminum-coated steel sheets. It is often used in high-temperature environments such as chimney pipes, ovens, lighting fixtures and fluorescent lampshades. At the same time, its thermal reflectivity is also twice that of galvanized steel sheets, so it is often used as a heat insulation material.

| Имя | Factory Directly Provide 0.12-2.0mm Zn-al Coating 275g Zinc Aluminum Sheet Coil |

| Стандарт | AISI,ASTM,GB,JIS |

| Толщина | 1.0-4.0mm |

| Ширина | Customized according to customer requirements |

| Терпимость | +/-0.02mm |

| Поверхностная обработка | Unoil,dry,chromate passivated, non-chromate passivated |

| Вес катушки | 3-8 tons |

| Техника | Hot rolled, cold rolled |

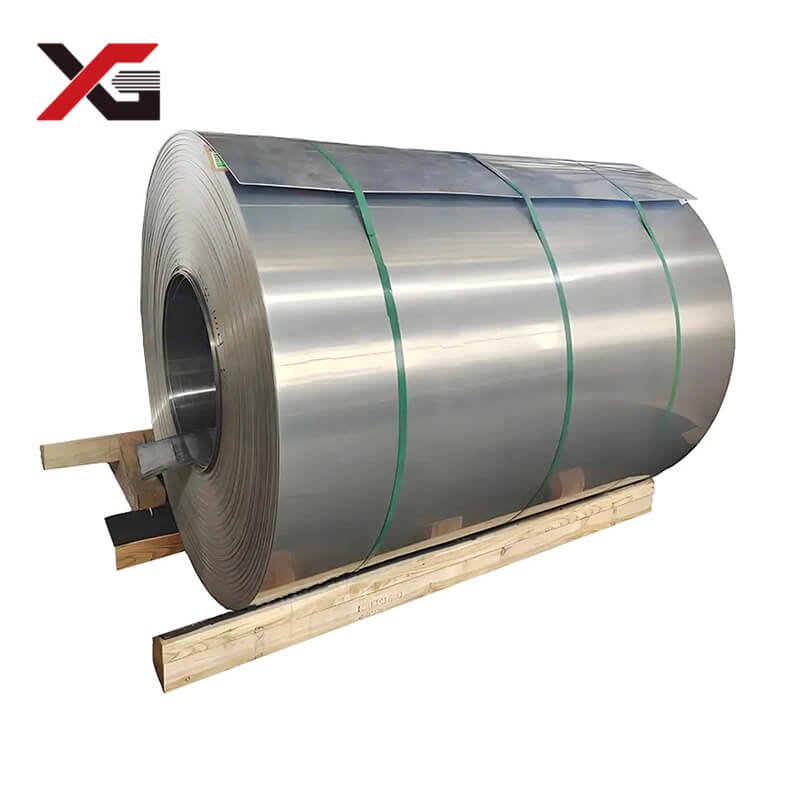

| Упаковка | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve |

| Сертификация | ISO 9001-2008,SGS,CE,BV |

| MOQ | 22 TONS (in one 20ft FCL) |

| Delivery | 15-20 days |

| Monthly Output | 30000 tons |

| Описание | With super corrosion resistance, rust and oxidation resistance, self-repairing of cuts,high hardness and high strength resistance to abrasion, easy to extend and easy to process, etc., and its life expectancy can reach more than 20 times that of ordinary galvanized products. |

| Remarks | Insurance is all risks and accept the third party test |

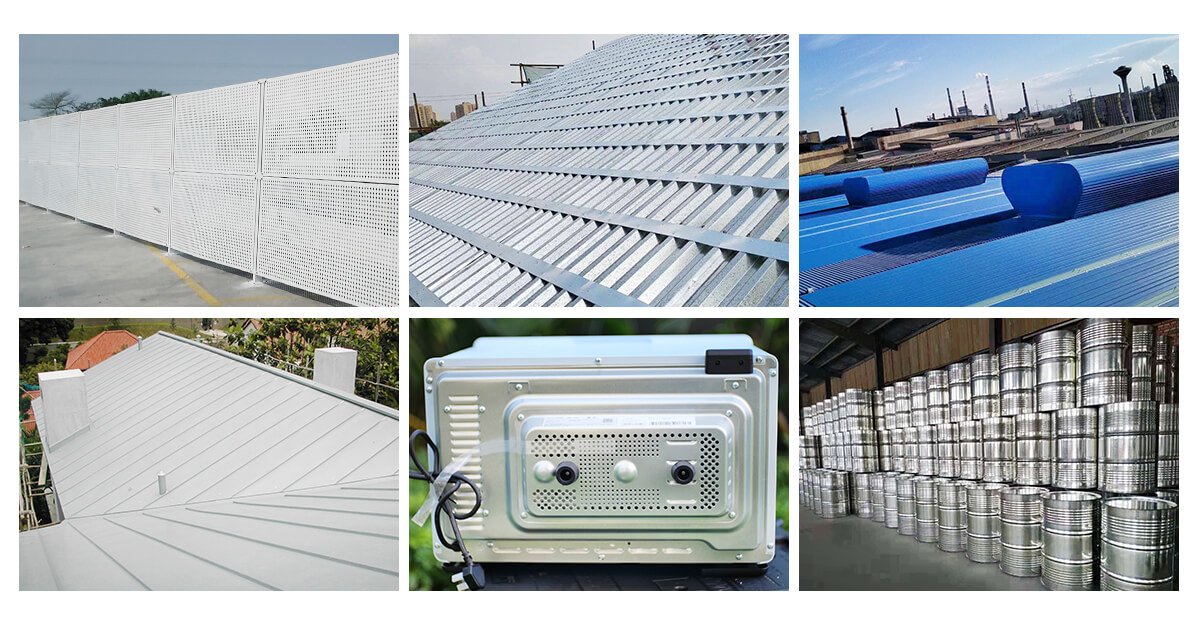

Product Application

Due to its unique properties, galvanized steel coils have been widely used in many fields. In the construction field, it is often used in roofs, walls, garages, soundproof walls, pipes and modular houses, etc. It can not only effectively resist the erosion of the natural environment, but also extend the service life of the building. In the automotive field, galvanized steel coils can be used to manufacture mufflers, exhaust pipes, wiper accessories, fuel tanks, truck boxes and other parts to improve the safety and service life of the car. In addition, in the field of home appliances, galvanized steel coils also play an important role. For example, it can be seen in home appliances such as refrigerator back panels, gas stoves, air conditioners, and electronic microwave ovens. In terms of agricultural use, galvanized steel coils are often used as building materials in pig houses, chicken houses, granaries, and greenhouse pipes.

Проектные кейсы

Дополнительные технологии обработки

Гальванизированный лист и катушка могут быть обработаны с помощью различных процессов, таких как резка, сварка, удары и нажатие, и размер цинковых хлопьев можно выбрать.

Упаковка продукта

Транспортировка продукции